Automation is reshaping how cultivated meat is produced, offering a clear path to reducing costs and scaling up production. While manual methods are suitable for small-scale research, they become inefficient and expensive at larger volumes. Automated systems, despite higher upfront costs, significantly lower ongoing expenses, improve efficiency, and reduce labour demands. Here's the key takeaway:

- Manual bioprocessing has lower initial costs but struggles with scaling, requiring more labour and resources.

- Automation requires a substantial investment but delivers long-term savings, higher efficiency, and consistent quality.

For the UK market, where labour and energy costs are high, automation is the only viable option to make cultivated meat affordable - potentially reducing costs to around £63 per kilogram with the potential to drop further as technology advances. This shift is critical for bringing cultivated meat to supermarket shelves at competitive prices.

Main Cost Factors in Cultivated Meat Bioprocessing

The production of cultivated meat is heavily influenced by three main cost drivers: labour, bioreactors, and cell-culture media. Together, these factors make up over 80% of the total production costs [2]. By comparing manual and automated systems, it becomes clear why automation is critical for achieving commercial viability. Let’s take a closer look at how each of these factors is managed in both approaches.

Labour and Staffing Costs

In manual bioprocessing, labour is a constant and significant expense. Technicians are responsible for monitoring key parameters like pH, temperature, oxygen levels, and cell differentiation. They also handle tasks such as harvesting and ensuring sterility, which often requires coverage over multiple shifts. For a large-scale operation producing 540,000 kg annually, with a capital investment of £46 million, labour remains a major cost that must be addressed to achieve profitable returns [2].

Automation transforms this dynamic by integrating sensors, digital controls, and AI to streamline processes. While it reduces the need for constant manual oversight, it doesn’t eliminate the need for skilled workers. Instead, these workers are redirected to more strategic roles, such as bioprocess engineering and facility management, shifting the focus from routine monitoring to high-value tasks [4].

Equipment and Capital Expenditure

Manual methods rely on small-scale tools like tissue culture flasks and well-plates, which are impractical for scaling up. To produce just 1 kg of cultivated meat manually, a working volume of 2,900 litres would be required [5]. This sheer scale makes manual production unsuitable for commercial operations.

Automated bioreactors, on the other hand, vastly improve efficiency. For example, a Stirred Tank Bioreactor needs only 570 litres to produce the same 1 kg of meat, while a Hollow Fibre Bioreactor requires just 1.4 litres [5]. However, this efficiency comes at a cost. Setting up a large-scale automated facility capable of producing 540,000 kg annually demands a significant upfront investment of around £46 million [2]. Despite this initial expense, automation offers benefits like higher cell densities, consistent yields, and smaller facility footprints, all of which are essential for remaining cost-competitive in the long term.

Consumables, Utilities, and Risk

Cell-culture media represents the largest ongoing expense in cultivated meat production. Manual systems, which often operate as open batches, struggle to optimise media usage and typically have minimal recycling capabilities. Automated systems address this issue by incorporating media recycling technologies. These systems retain valuable components such as glucose and proteins while removing growth-inhibiting waste products like lactate and ammonia [5]. As a result, automated facilities can produce 1 kg of cultivated meat using just 8 to 13 litres of media, compared to 42 litres in less efficient setups [1].

Contamination is another critical concern. Manual handling increases the risk of batch failures due to human error. Automated systems, particularly those using single-use bioreactors, significantly lower contamination risks and reduce the need for extensive cleaning procedures [5]. Energy management also benefits from automation. Maintaining the required 37°C for mammalian cell growth becomes far more efficient with digital controls managing heating and cooling, rather than relying on manual adjustments [5].

Manual Bioprocessing Costs

Manual bioprocessing relies on traditional lab techniques, which come with high ongoing costs, making it unsuitable for large-scale commercial production.

Workflow and Operating Costs

In manual bioprocessing, nearly every step requires hands-on attention. Technicians must prepare cell-culture media, monitor cell health and characteristics, transfer cells between vessels, and ensure sterile conditions are maintained. This process demands a highly skilled team, including operations engineers, microbiologists, and scientists, which significantly increases labour costs. The reliance on manual workforces drives up operational expenses, especially given the need for constant staffing.

The inefficiencies of manual methods further add to the cost. For instance, the dependence on planar culture systems like flasks and well-plates limits the ability to achieve the high cell densities essential for cost-efficient production. This setup not only wastes labour but also leads to excessive media use, compounding the problem.

These inefficiencies naturally create challenges when trying to scale up production.

Scaling Challenges

Scaling manual bioprocessing methods presents a significant hurdle. Since these processes are labour-intensive, scaling up means proportionally increasing labour, workspace, and the risk of contamination. This linear cost increase has been referred to as a "bottleneck", highlighting the urgent need to shift from manual techniques to automated systems to ensure financial viability [5].

Additionally, manual handling introduces variability and a higher risk of contamination, which in turn requires expensive quality assurance measures. This variability makes it difficult to consistently produce the uniform quality consumers expect [5].

Manual Process Costs: Pros and Cons

Below is a summary of the key advantages and drawbacks of manual bioprocessing:

| Feature | Advantages | Disadvantages |

|---|---|---|

| Initial Investment | Lower upfront costs using standard lab equipment | Requires substantial incubator space for scaling up |

| Labour Requirements | Utilises existing lab expertise and protocols | High ongoing costs; demands 24/7 staffing |

| Scalability | Effective for research and small pilot batches | Limited by surface area in flasks; costs rise linearly |

| Consistency | Allows flexibility for experimental changes | Prone to human error and inconsistent quality |

| Contamination Risk | Easier to manage on a small scale | Increased risk with open handling and manual transfers |

| Media Efficiency | Simple batch processes | Poor recycling of media, leading to higher waste |

| Space Efficiency | Minimal space needed for small operations | Requires extensive physical space as scale increases |

The core issue with manual bioprocessing lies in its inability to deliver the economies of scale necessary for commercial success. While it remains a valuable tool for research and development, achieving affordable cultivated meat for UK consumers will depend on transitioning to automated systems, which can significantly lower production costs per kilogram.

Automated Bioprocessing Costs

Automation is reshaping the economics of cultivated meat production, addressing the challenges of manual methods. While the upfront investment for automated bioprocessing is substantial, it offers significant long-term savings and enables large-scale manufacturing.

Technologies and Investment Requirements

Automated systems replace manual tissue culture flasks with industrial bioreactors that are computer-controlled, ensuring precision and efficiency. Key technologies include Stirred Tank Bioreactors (STRs), Hollow Fibre Bioreactors (HFBs), and Packed Bed Bioreactors (PBBs). These advanced systems manage nutrient delivery and waste removal through digital monitoring, reducing the need for manual intervention [5].

Single-use bioreactors (SUBs) are gaining traction for vessels up to 2,000 litres. These disposable systems eliminate the need for time-intensive cleaning procedures between batches, reducing downtime and contamination risks. However, they do come with higher per-batch operating costs [5]. For instance, a facility aiming to produce 540,000 kg annually may require an initial investment of approximately £60 million [2].

In addition to bioreactors, automated facilities rely on seed trains - a process of transferring cells to progressively larger reactors - and sophisticated aeration systems to meet the high oxygen demands of cell cultures. Digital quality assurance tools continuously monitor factors like cell viability and protein content, ensuring consistent results [5].

Labour Efficiency and Yield Improvements

Automation significantly reduces the need for manual labour while improving the consistency and quality of the final product. As Scott J. Allan from the University of Bath explains:

"To make cultured meat production financially viable it will be necessary to utilise a less manual-labour intensive and more automated and efficient process of production than lab-scale tissue culture, in the form of a bioprocess." [5]

By minimising the need for around-the-clock staffing, automation cuts labour costs and improves reproducibility. Manual handling often introduces variations and increases the risk of batch failures, but automated systems mitigate these issues.

The efficiency gains are striking. Automated STRs achieve cell densities between 1.9 × 10⁵ and 2 × 10⁶ cells per millilitre, while advanced HFBs reach densities of 10⁸ to 10⁹ cells per millilitre. To put this into perspective, an advanced HFB requires just 1.4 litres of working volume to produce the same output as 2,900 litres with manual methods - over 2,000 times more efficient [5].

These advancements not only enhance productivity but also make scaling operations more feasible, laying the groundwork for economic sustainability.

Scalability and Long-Term Savings

One of the key advantages of automation is its ability to spread high capital costs across larger production volumes, driving down the cost per kilogram as facilities scale up. At full capacity, large-scale facilities could achieve a wholesale cost of approximately £63 per kg for cultivated meat [2]. Although this is still higher than conventional meat prices, it represents a significant improvement over small-scale manual methods.

The primary cost contributors - cell-culture medium, bioreactors, and labour - account for over 80% of total production expenses [2]. Automation addresses these factors by reducing labour intensity and improving bioreactor efficiency. Over time, continuous production, reduced waste, and the integration of renewable energy sources further lower operating costs.

The table below compares the efficiency and scalability of various bioreactor technologies:

| Bioreactor Type | Achievable Cell Density (cells/mL) | Working Volume for 1kg Meat | Relative Efficiency |

|---|---|---|---|

| Tissue Culture Flasks (Manual) | ~1.0 × 10⁵ | 2,900 L | Baseline |

| Stirred Tank Bioreactors (STR) | 1.9 × 10⁵ – 2.0 × 10⁶ | 570 L | ~5× more efficient |

| Packed Bed Bioreactors (PBB) | 2.93 × 10⁶ | 110 L | ~26× more efficient |

| Hollow Fibre Bioreactors (HFB) | 10⁸ – 10⁹ | 1.4 L | Over 2,000× more efficient |

The move towards automation is transforming production economics. Though the upfront costs are high, the long-term benefits make automated bioprocessing the most practical path for delivering cultivated meat at competitive prices for UK consumers. This shift is essential for making cultivated meat an attractive option for shoppers in the UK.

sbb-itb-c323ed3

Manual vs Automated Bioprocessing: Cost Comparison

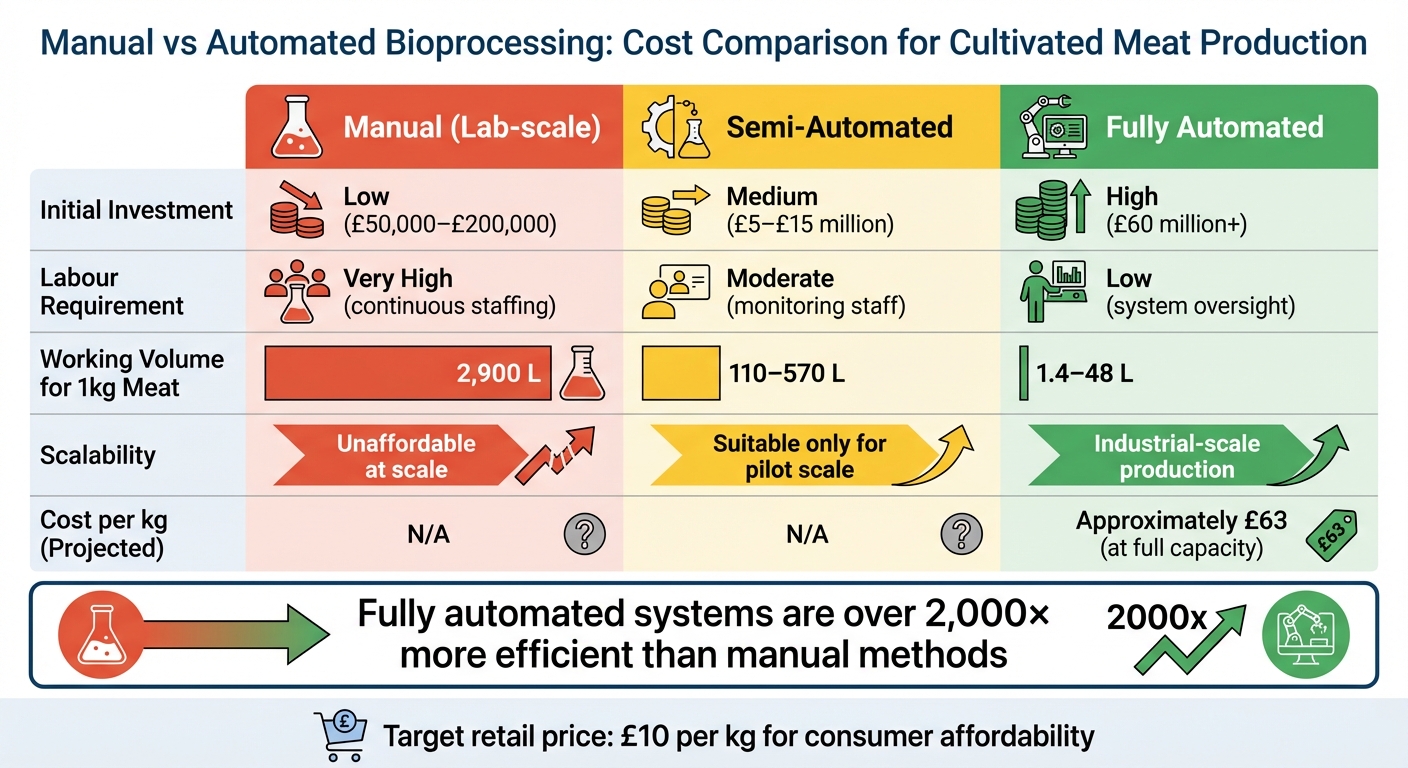

Manual vs Automated Bioprocessing Cost Comparison for Cultivated Meat Production

This section dives into the economics of manual and automated bioprocessing, examining how costs evolve over time and across different production scales.

Short-Term vs Long-Term Cost Dynamics

In the short term, manual bioprocessing has a clear cost advantage due to its lower initial investment. Basic equipment like tissue culture flasks, standard incubators, and general lab supplies are sufficient at the research stage, avoiding the need for expensive facilities.

However, scaling up tells a very different story. Manual methods quickly become labour-intensive and expensive. To produce just 1 kg of product manually, approximately 2,900 litres of flasks are required - a process that demands significant staffing and resources [5].

On the other hand, automated systems come with a hefty initial price tag but offer substantial long-term savings. These systems reduce labour costs, improve yield consistency, and maintain quality. For instance, a fully automated facility capable of producing 540,000 kg annually might require an upfront investment of around £60 million. Yet, it can achieve wholesale costs of approximately £63 per kilogram [2]. As production scales up, the high fixed costs are distributed across more units, significantly lowering the per-kilogram cost.

These cost dynamics are particularly pronounced when considering the UK market.

UK-Specific Cost Factors

In the UK, where labour costs are high, automation becomes even more appealing. Manual bioprocessing depends heavily on skilled technicians, and the continuous monitoring required at scale adds to the financial burden. Energy costs also play a role, as bioreactors must maintain a steady 37°C [5].

Growth media is another major expense in cultivated meat production. Along with bioreactors and labour, it accounts for over 80% of total production costs [2]. To achieve competitive pricing - around £10 per kilogram - growth factors and recombinant proteins need to be reduced to just 10% of the overall expenses, equating to roughly £1 per kilogram of meat [1]. This efficiency goal requires using only 8 to 13 litres of media per kilogram of cultivated meat [1].

Cost Scenarios: Manual, Semi-Automated, and Fully Automated

The table below highlights the key cost factors for different production approaches:

| Production Approach | Initial Investment | Labour Requirement | Working Volume for 1kg Meat | Scalability | Cost per kg (Projected) |

|---|---|---|---|---|---|

| Manual (Lab-scale) | Low (£50,000–£200,000) | Very High (continuous staffing) | 2,900 L | Unaffordable at scale | N/A |

| Semi-Automated | Medium (£5–£15 million) | Moderate (monitoring staff) | 110–570 L | Suitable only for pilot scale | N/A |

| Fully Automated | High (£60 million+) | Low (system oversight) | 1.4–48 L | Industrial-scale production | Approximately £63 (at full capacity) |

For comparison, a small manual setup might cost around £100,000 to establish but cannot achieve affordable large-scale production. Semi-automated facilities, such as those using packed bed bioreactors, reduce the working volume significantly - to as little as 110 litres per kilogram. However, they still require considerable labour input [5]. Fully automated systems, like those employing hollow fibre bioreactors, achieve unmatched efficiency, requiring only about 1.4 litres per kilogram - making them over 2,000 times more efficient than manual setups [5].

These scenarios clearly demonstrate why automation is critical for scaling production and achieving affordable prices, paving the way for more accessible cultivated meat options in the UK market.

What Automation Means for Consumers

Automation isn't just reshaping production methods - it’s changing the way consumers experience and access cultivated meat.

Making Cultivated Meat Affordable and Accessible

The shift from manual to automated bioprocessing is a game-changer for bringing cultivated meat to UK dinner tables. Achieving a price point of around £10 per kilogram is critical for making this option a regular choice for consumers, and automation is the key to getting there [1].

Here’s why: automation significantly slashes production costs. For example, automated precision fermentation can cut the cost of certain recombinant proteins by an impressive 99% [1]. Similarly, research shows that a commonly used stem cell medium can be produced for 97% less than its current commercial price [4]. Scaling up with industrial bioreactors - those massive tanks holding 20,000 litres or more - further drives down costs and makes large-scale production feasible [3]. Beyond affordability, automation also ensures reliable and safe products, which boosts consumer trust.

Building Trust Through Consistency and Safety

Automation doesn’t just make cultivated meat cheaper - it makes it better. Automated bioprocessing systems use advanced tools like integrated sensors and machine learning to keep a constant check on critical factors such as pH levels, metabolites, and biomass [4]. This level of precision ensures every batch meets consistent quality standards, which is much harder to achieve with manual methods.

Another major advantage is safety. Automated precision fermentation creates a pathogen-free production environment by removing risks linked to animal-derived contaminants [1]. Closed, automated systems maintain strict food-grade aseptic conditions, reducing the chances of contamination or batch failure [3]. A notable example of this progress came in early 2023 when GOOD Meat received regulatory approval in Singapore to sell cultivated chicken made with serum-free media - a milestone that highlights how automation can scale up production without compromising safety [4].

Helping Consumers Understand the Impact of Automation

As automation drives down costs and enhances quality, platforms like Cultivated Meat Shop play a vital role in educating consumers. For UK shoppers, understanding how production technologies influence pricing and availability is becoming increasingly important. Cultivated Meat Shop simplifies this by offering clear, reliable information that connects the dots between automation, affordability, and accessibility. It’s about making the science behind cultivated meat approachable, so consumers can see how these advancements are shaping the future of food.

Conclusion

The cost difference between manual and automated bioprocessing is striking. Manual methods simply can't scale to match the price competitiveness of conventional meat.

Over 80% of production costs are tied to three key factors, and without automation, these expenses remain unmanageable [2].

Automation fundamentally changes the economics of production. For instance, large-scale facilities equipped with bioreactors of 20,000 litres or more can reduce wholesale costs to around £48 per kilogram, as outlined earlier [2]. A dramatic 99% reduction in the cost of recombinant proteins, compared to traditional biopharmaceutical production, is a critical step [1]. Additionally, achieving media efficiency of 8 to 13 litres per kilogram of meat - far below the 42 litres required by less efficient systems - is another game-changer [1].

These technological advancements directly impact consumer pricing and product consistency. For shoppers in the UK, this means cultivated meat could shift from being a costly novelty to an affordable, everyday option. Instead of a £18 burger that discourages widespread adoption, automation makes it possible to offer products that fit comfortably into weekly grocery budgets [2]. Beyond affordability, automated systems also ensure consistent quality, enhanced safety, and a stable supply chain - factors that are crucial for earning consumer trust.

This is where Cultivated Meat Shop steps in. As production technology advances and costs drop, the platform serves as a bridge, helping consumers understand how automation shapes pricing. By breaking down the science behind cultivated meat production, Cultivated Meat Shop provides UK shoppers with clear insights into how industrial-scale processes make cultivated meat both accessible and dependable.

FAQs

How does automation reduce costs in cultivated meat production over time?

Automation has the potential to drastically lower the labour costs tied to cultivated meat production. Currently, labour accounts for about 30% of production costs, but automation could reduce this by as much as 20%. By streamlining processes and allowing bioreactors to produce larger outputs, automation helps distribute fixed costs over higher production volumes. This, in turn, drives down the per-kilogram cost of cultivated meat over time.

For producers, these advancements don’t just improve cost efficiency - they also pave the way for scaling operations to meet growing demand. As automation continues to evolve, it plays a critical role in making cultivated meat a more affordable and accessible option compared to traditional meat.

How does automation make cell-culture media use more efficient?

Automation plays a key role in improving the efficiency of cell-culture media usage through the use of continuous-flow bioreactors and precise dosing systems. These advanced tools allow for achieving higher cell densities while keeping waste to a minimum, which means significantly less media is needed.

This optimised approach can lead to a reduction in media costs of up to 20%, bringing expenses down to around £0.63 per litre. By making better use of resources, automation not only helps cut costs but also encourages more sustainable production practices in the cultivated meat industry.

Why is automation important for scaling cultivated meat production in the UK?

Automation is transforming how cultivated meat is produced, making the process more efficient and affordable. Labour-intensive steps, which often make up about 30% of production costs, can see a reduction of up to 20% with automation. This not only reduces expenses but also supports the use of larger, continuous-flow bioreactors - key for achieving the economies of scale necessary to bring down prices and make cultivated meat more accessible across the UK.

By integrating automation, producers can scale up operations to meet increasing demand while ensuring consistent quality. This paves the way for a more sustainable and widely available alternative to traditional meat.